|

A hollow structural section (HSS) is a type of metal profile with a hollow tubular cross section. In some countries they are referred to instead as a structural hollow section (SHS). Most HSS are of circular or rectangular section, although other shapes are available, such as elliptical. HSS is only composed of structural steel per code. HSS is sometimes mistakenly referenced as hollow structural steel. Rectangular HSS are also called tube steel or structural tubing. Circular HSS are sometimes mistakenly called steel pipe though true steel pipe is actually dimensioned and classed differently than HSS. The corners of HSS are heavily rounded, or chamfered, at radii approximately twice the wall thickness. The wall thickness is uniform around the section. In the UK, the terms are circular and rectangular hollow section (CHS and RHS). However, the dimensions and tolerances differ slightly from HSS. A steel mill or steelworks is an industrial plant for the manufacture of steel. Steel is an alloy of iron and carbon. It is produced in a two-stage process. First, iron ore is reduced or smelted with coke and limestone in a blast furnace, producing molten iron which is either cast into pig iron or carried to the next stage as molten iron. In the second stage, known as steelmaking, impurities such as sulfur, phosphorus, and excess carbon are removed and alloying elements such as manganese, nickel, chromium and vanadium are added to produce the exact steel required. In the late 19th Century and early 20th Century the world’s largest steel mill was located in Barrow-in-Furness, UK. Today, the world’s largest steel mill is in Gwangyang, South Korea. Steel mills turn molten steel into blooms, ingots, slabs and sheet through casting, hot rolling and cold rolling A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow  liquids and gases (fluids), slurries, powders, masses of small solids. It can also be used for structural applications; hollow pipe is far stronger per unit weight than solid members. In common usage the words pipe and tube are usually interchangeable, but in industry and engineering discipline the terms are uniquely defined. Depending on the applicable standard to which it is manufactured, pipe is generally specified by a nominal diameter with a constant outside diameter (OD) and a schedule that defines the thickness. Tube is most often specified by the OD and wall thickness, but may be specified by any two of OD, inside diameter (ID), and wall thickness. Pipe is generally manufactured to one of several international and national industrial standards. While similar standards exist for specific industry application tubing, tube is often made to custom sizes and a broader range of diameters and tolerances. Many industrial and government standards exist for the production of pipe and tubing. The term "tube" is also commonly applied to non-cylindrical sections, i.e., square or rectangular tubing. In general, "pipe" is the more common term in most of the world, whereas "tube" is more widely used in the United States. Both "pipe" and "tube" imply a level of rigidity and permanence, whereas a hose (or hosepipe) is usually portable and flexible. Pipe assemblies are almost always constructed with the use of fittings such as elbows, tees, and so on, while tube may be formed or bent into custom configurations. For materials that are inflexible, cannot be formed or where construction is governed by codes or standards, tube assemblies are also constructed with the use of tube fittings.

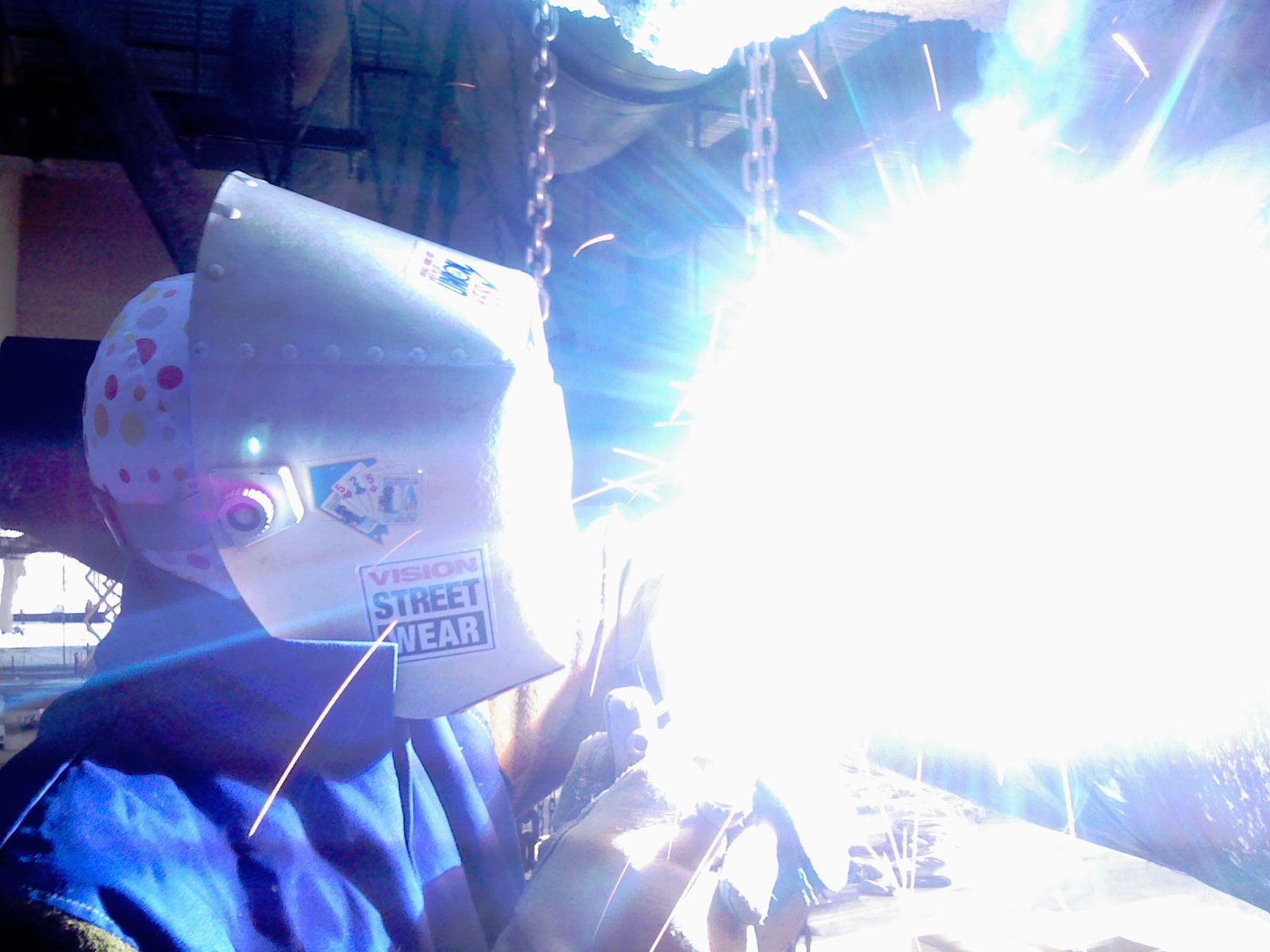

Steel pipes

Plastic (PVC) pipes in USA Pipe fitting is the occupation of installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work involves selecting and preparing pipe or tubing, joining it together by various means, and the location and repair of leaks. Pipe fitting work is done in many different settings: HVAC, manufacturing, hydraulics, refineries, computer chip fab plants, power plant construction and other steam systems. Pipe fitters (sometimes called simply "fitters") are represented in the USA and Canada by the United Association of Journeymen and Apprentices of the Plumbing and Pipe Fitting Industry of the United States and Canada. Fitters work with a variety of pipe and tubing materials including several types of steel, copper, iron, plastic, aluminium. Pipe fitting is not plumbing, the two are related but separate trades. Pipe fitters who specialize in fire prevention are called Sprinklerfitters, another related, but separate trade.

From Wikipedia, the free encyclopedia : Manufacture of steel tubes, pipes, hollow profiles and related fittings |